-

A better way to hire,we have everything you require!

-

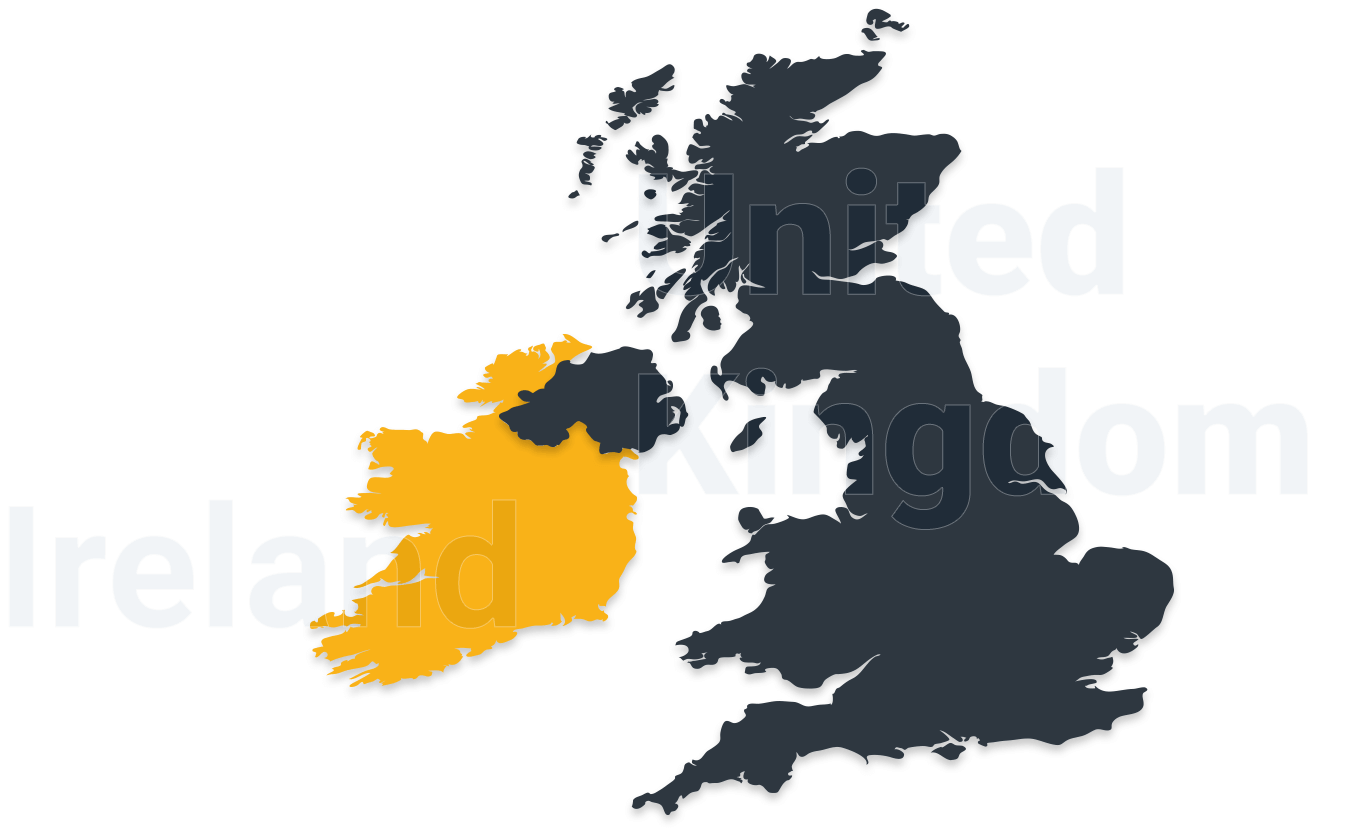

We equip your successthroughoutthe UK & Ireland!National Coverage

-

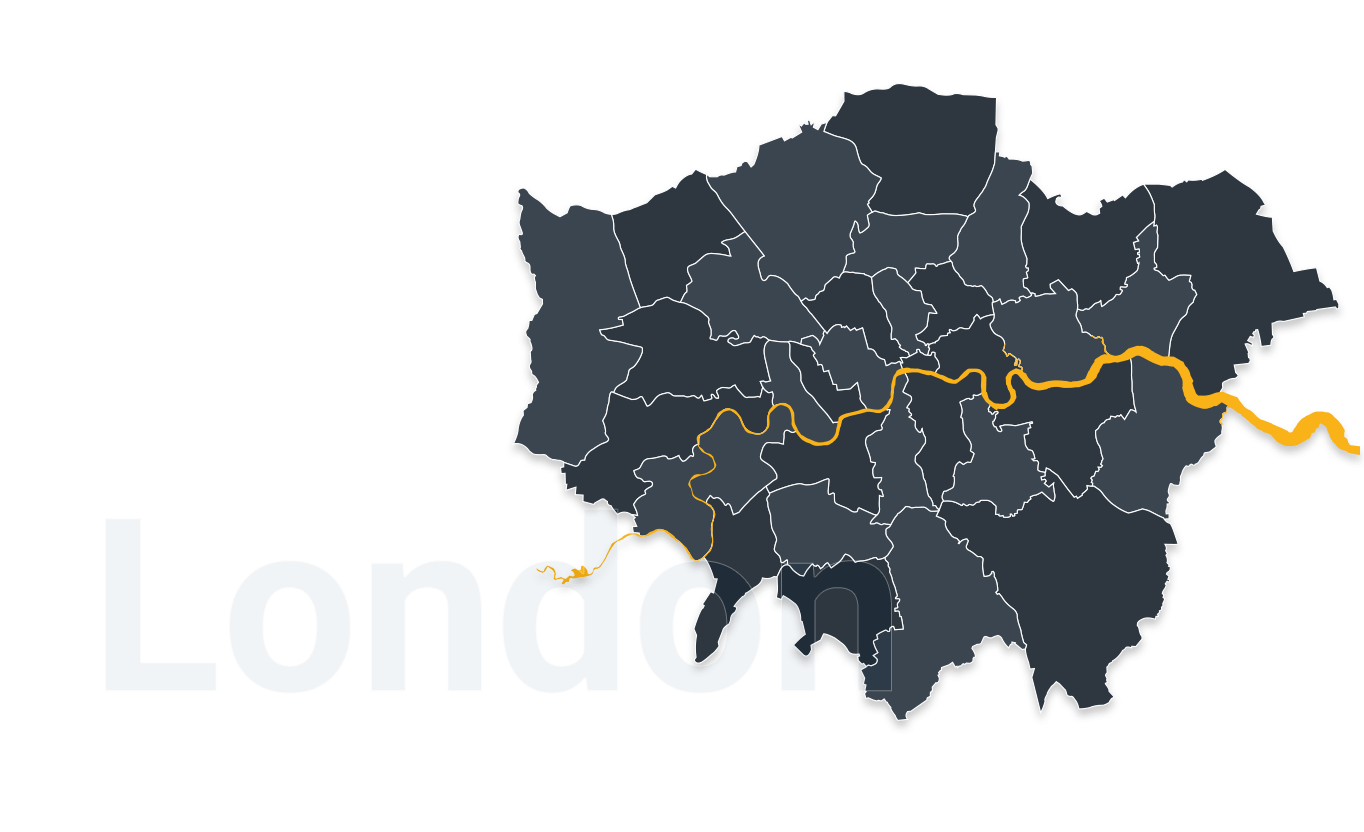

We’ve got Londoncovered!Over 20 depots within the M25 boundaryNext day delivery guaranteed

WHO WE ARE?

We are a tool, plant and site equipment hire specialist supplying comprehensive solutions for construction, automotive, solar panel and many more industries. Our range of plant and equipment to hire include everything from telehandlers, scissor and boom lifts up to towers, grinders, and cordless drills. No job too small.

Toolmach is a gateway to the entire UK, Ireland and Western Europe hire industry. We provide you with the equipment being supplied by some of the most professional and efficient companies in the industry.

Since its establishment Toolmach has grown continuously and we are very pleased to share our progress with you. With many years of experience in the tools and machinery industry, our service is complemented by an experienced and knowledgeable staff, who are here to assist you with advice and support throughout the entire process. We hope you enjoy browsing our website and do not hesitate to use the contact page or links for further assistance.

Our mission is to save time and money by providing equipment at short notice and offering national (and beyond) coverage at local rates with competitive transport costs. We focus on providing exceptional customer service using our extensive industry knowledge and experience, to help our counterparties benefit from it. We are passionate about what we do and we work determinedly to ensure our customers are satisfied with every order.

Hire

Toolmach will happily fulfil all your tool, equipment and plant hire needs. We have a diverse range of customers working on construction, industrial and energy projects. We would welcome the opportunity to support your projects by offering a quality service alongside competitive prices. All the rates depend on many factors such as geographical area, collection/delivery, length of the rental period, the urgency of order. Therefore for further information and pricing, please call us on 0800 433 7275, use Contact Us form or send us an email at hire@toolmach.co.uk

Training

We can offer a comprehensive range of courses, that are held at over 50 locations across the UK & Ireland. These courses are professionally delivered by fully qualified instructors to both, individuals and organisations. Please choose one of the courses you are interested in, tell us your location and leave the rest to us.

For more information or to discuss your bespoke training needs, please contact us using the below details:

-

IPAF Courses

IPAF Operator

1a Static Vertical

1b Static Boom

3a Mobile Vertical

3b Mobile Boom

- IPAF Demonstrator

- IPAF MEWP Harness Use and Inspection

- IPAF MEWPs for Managers

- IPAF PAL+

- The IPAF Competent Assessed Persons (CAP)

-

PASMA Courses

PASMA Standard Access Tower

PASMA Low Level Access

PASMA Combined (Standard & Low Level)

-

CITB Construction Skills

Site Management Safety Training Scheme (SMSTS)

Site Supervisors Safety Training Scheme (SSSTS)

-

First Aid

First Aid at Work

Emergency First Aid at Work

-

CPCS

Lifting - Appointed Person CPCS - A61

CPCS Slinger/ Signaller - A40

-

Transport and Mobile Plant Training

Forklift Operator

Telehandler Operator

PROJECTS

Our clients operate across a wide range of market sectors including automotive, construction, civil engineering, renewable energy, oil & gas and many more. Explore a selection of our client’s case studies, which we have supplied tools and plant for. If you have a specific project and need to discuss equipment options and availability, please don’t hesitate to contact us.

Nissan Manufacturing

Nissan Manufacturing was granted a permission for a new paint facility at Washington Rd, Sunderland. The new building was to replace existing paint facilities for the plant’s Line 1. The new section is a 216m long and 50m wide, 3 storey building, linked to existing paint shop via a bridge. One of our clients participated in the project of montaging and installing all the painting equipment in the new paint shop. We have been successfully delivering them tools, plant and machinery for over 6 months. For this project, they required machines, such us 3.0t and 5.5t forklifts, 17m telehandler, 26m cherry picker, SLA25 Genie Lifts and many more. Our on-time deliveries and service helped to successfully deliver the whole project before the deadline.

Thames Valley Science Park

The Thames Valley Science Park in Reading features some of the UK’s first high-energy proton beam innovative treatments. This new facility includes a linear accelerator, as well as a CT Suite and an MRI. This top cancer technology will treat up to 500 patients a year. These particular laboratories have been built by our client, who specialise in building medical facilities, especially x-ray, proton and radiology laboratories, as well as nuclear medicine facilities. We are proud, that we could participate in this project and were able to deliver tools, equipment and machinery throughout three stages of the project, from summer 2017 till spring 2018. We were providing everything from telehandlers, scissor lifts, forklifts at the first stage, up to smaller equipment, such as podium steps, lighting, drills and many more at the further stages. Which eventually lead to finishing the project to the highest possible standards.

Greater London

The greater majority of our business lies within the London area. Most of our customers work in London, having projects ranging from small, medium up to the large-scale ones. These include domestic, commercial and industrial realisations and developments. We supply our clients with floor sander kits for small flooring jobs, mini and medium excavators and dumpers for variously sized extensions, different types of Material Genie Lifts for installation of steel beams. We also work closely with basement excavation companies, supplying them with Masonry Acrow Props, Trench Struts, Trench Sheets, GASS Props and many more. We also provide heavy haulage services to transport our clients own plant and accommodation between different sites in London and the surrounding area. No job too big or too small, we have you covered!

Viridor Transfer Station

In 2015 Viridor started a constriction of the £205m Energy Recovery Facility (ERF) at existing landfill and recycling site in Beddington, South London. This facility has been designed to transfer non-hazardous residual waste into energy. It can process around 275,000 tonnes of waste a year and generate of up to 30MW of electricity enough to power the facility itself plus around 30,000 homes. One of our clients were supplying and installing the new facility with cable trays, control cables, earthing system, LV switchgear & equipment and I/O cabinets. We have equipped them with a couple of cable drum jacks, so they could finish the task. Some of their works were at heights, which involved powered access equipment to be used. For this reason, we have supplied them with 10m electric scissor lifts and 15m bi-fuel cherry picker, alongside with lots of different size podium and slimline steps. The whole equipment allowed them to finish their installation project to the highest possible standard.

Imperial Tobacco

In 2014 Imperial Tobacco announced, that due to declining sales they would be moving out of the UK, which meant the closure of the Nottingham factory. One of our clients were involved in relocating part of the factory, including large and heavy factory equipment and machinery from the UK to Germany. We have been asked to deliver a couple of different forklifts on a short notice. These included 3.5 ton and 5.5 ton LPG forklifts, and 8ton diesel forklifts. All the machines had to meet closed height restrictions within the buildings. Everything had to be delivered on time, so all the lorries would be loaded on time, and would be able to get to Germany as scheduled. Although there were initial problems with the availability, we have finally managed to meet all the requirements and deliver on time all the equipment. The relocation went smoothly and within the time-scale, which we made a small contribution to.

Heathrow Airport

International Airlines Group (IAG) in 2017 began a construction of its new terminal, a £55 million premium facility at Heathrow Airport in London. The new facility will be two times bigger than the existing one and will handle the ever-growing demand for express prioritised shipments and pharmaceuticals. The New Premia features 11 truck docks and an additional 20 workstations for a break and build, everything temperature controlled between 15 and 25 degrees Celsius. One of our clients precipitated in this big enterprise, and we have supplied them with a lot of machines required for the scope of the project. We delivered them a couple of scissor lifts, cherry pickers and forklifts, all with non-marking tyres. The forklifts were 2.5 – 3.5t with lifting height minimum of 5.5 meters. We have also delivered them a 17m telehandler fitted with a diesel particulate filter (DPF) and coveralls, so they could work indoors. The delivery was on time and thanks to our service they were able to finish all works within timeframes.

-

Nissan Manufacturing

Nissan Manufacturing was granted a permission for a new paint facility at Washington Rd, Sunderland. The new building was to replace existing paint facilities for the plant’s Line 1. The new section is a 216m long and 50m wide, 3 storey building, linked to existing paint shop via a bridge. One of our clients participated in the project of montaging and installing all the painting equipment in the new paint shop. We have been successfully delivering them tools, plant and machinery for over 6 months. For this project, they required machines, such us 3.0t and 5.5t forklifts, 17m telehandler, 26m cherry picker, SLA25 Genie Lifts and many more. Our on-time deliveries and service helped to successfully deliver the whole project before the deadline.

-

Thames Valley Science Park

The Thames Valley Science Park in Reading features some of the UK’s first high-energy proton beam innovative treatments. This new facility includes a linear accelerator, as well as a CT Suite and an MRI. This top cancer technology will treat up to 500 patients a year. These particular laboratories have been built by our client, who specialise in building medical facilities, especially x-ray, proton and radiology laboratories, as well as nuclear medicine facilities. We are proud, that we could participate in this project and were able to deliver tools, equipment and machinery throughout three stages of the project, from summer 2017 till spring 2018. We were providing everything from telehandlers, scissor lifts, forklifts at the first stage, up to smaller equipment, such as podium steps, lighting, drills and many more at the further stages. Which eventually lead to finishing the project to the highest possible standards.

-

Greater London

The greater majority of our business lies within the London area. Most of our customers work in London, having projects ranging from small, medium up to the large-scale ones. These include domestic, commercial and industrial realisations and developments. We supply our clients with floor sander kits for small flooring jobs, mini and medium excavators and dumpers for variously sized extensions, different types of Material Genie Lifts for installation of steel beams. We also work closely with basement excavation companies, supplying them with Masonry Acrow Props, Trench Struts, Trench Sheets, GASS Props and many more. We also provide heavy haulage services to transport our clients own plant and accommodation between different sites in London and the surrounding area. No job too big or too small, we have you covered!

-

Viridor Transfer Station

In 2015 Viridor started a constriction of the £205m Energy Recovery Facility (ERF) at existing landfill and recycling site in Beddington, South London. This facility has been designed to transfer non-hazardous residual waste into energy. It can process around 275,000 tonnes of waste a year and generate of up to 30MW of electricity enough to power the facility itself plus around 30,000 homes. One of our clients were supplying and installing the new facility with cable trays, control cables, earthing system, LV switchgear & equipment and I/O cabinets. We have equipped them with a couple of cable drum jacks, so they could finish the task. Some of their works were at heights, which involved powered access equipment to be used. For this reason, we have supplied them with 10m electric scissor lifts and 15m bi-fuel cherry picker, alongside with lots of different size podium and slimline steps. The whole equipment allowed them to finish their installation project to the highest possible standard.

-

Imperial Tobacco

In 2014 Imperial Tobacco announced, that due to declining sales they would be moving out of the UK, which meant the closure of the Nottingham factory. One of our clients were involved in relocating part of the factory, including large and heavy factory equipment and machinery from the UK to Germany. We have been asked to deliver a couple of different forklifts on a short notice. These included 3.5 ton and 5.5 ton LPG forklifts, and 8ton diesel forklifts. All the machines had to meet closed height restrictions within the buildings. Everything had to be delivered on time, so all the lorries would be loaded on time, and would be able to get to Germany as scheduled. Although there were initial problems with the availability, we have finally managed to meet all the requirements and deliver on time all the equipment. The relocation went smoothly and within the time-scale, which we made a small contribution to.

-

Heathrow Airport

International Airlines Group (IAG) in 2017 began a construction of its new terminal, a £55 million premium facility at Heathrow Airport in London. The new facility will be two times bigger than the existing one and will handle the ever-growing demand for express prioritised shipments and pharmaceuticals. The New Premia features 11 truck docks and an additional 20 workstations for a break and build, everything temperature controlled between 15 and 25 degrees Celsius. One of our clients precipitated in this big enterprise, and we have supplied them with a lot of machines required for the scope of the project. We delivered them a couple of scissor lifts, cherry pickers and forklifts, all with non-marking tyres. The forklifts were 2.5 – 3.5t with lifting height minimum of 5.5 meters. We have also delivered them a 17m telehandler fitted with a diesel particulate filter (DPF) and coveralls, so they could work indoors. The delivery was on time and thanks to our service they were able to finish all works within timeframes.

CONTACT US

Welcome to Toolmach. If you have any questions about any of our products or services, please get in touch. We are open from Monday to Friday: 7.30 a.m. to 5.00 p.m.

- Copyright © 2026 Toolmach Ltd

- |

- Created by: bcweb.pl